Strengthening DC architecture with cryogenic cooling

AI’s power problem

AI factories are rapidly scaling, with single racks reaching ~200 kW and facilities moving towards gigawatt-class power demand.

The key bottleneck in AI infrastructure is no longer compute availability, but the energy cost of cooling. High-density GPUs require escalating power just to manage heat, eroding efficiency and margins.

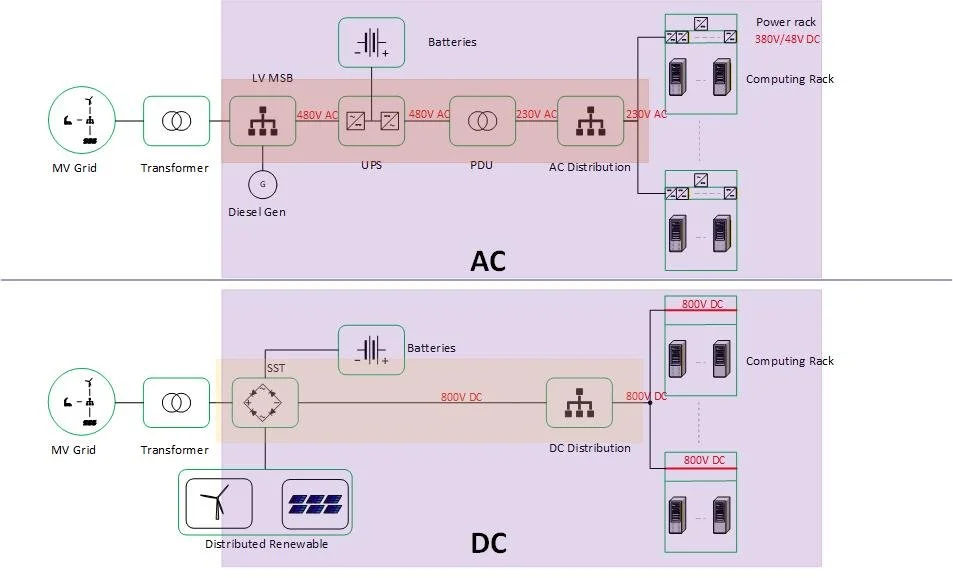

Beyond cooling, AI factories face a second structural constraint in traditional AC power distribution. As power levels rise, AC architectures suffer from conversion losses, bulky transformers, extensive cabling, and limited scalability. Multiple AC–DC conversions generate additional heat and energy loss, further amplifying cooling demand and positioning legacy AC distribution as a growing barrier to efficiency, density, and economic sustainability.

A new model for AI power and cooling

Cryogenic cooling enables direct, ultra-efficient heat removal at the source, allowing GPUs to operate at extreme densities without the escalating energy penalties of traditional cooling systems.

At the same time, a DC power distribution network simplifies power delivery, reduces conversion losses, and eliminates much of the infrastructure and heat overhead inherent in AC architectures.

Together, cryogenic cooling and DC distribution form the foundation of a new AI factory model — one that supports gigawatt-scale compute with higher efficiency, greater density, and sustainable long-term economics.

Image ©ZAP Power Ltd

Benefits that compound

Strategic efficiency

Holistic system benefits on the computation rack and power plant, including higher power density, reduced cabling mass, and lower overall system impedance drive the operating expenditure savings that conventional PUE metrics do not capture.

Improved computation

In facilities operating within a cryogenic environment, the cryogenically cooled DC network thermally anchors the liquid cooling system. This allows compute racks to operate within a more stable and controlled temperature range, which is critical for AI workloads subject to extreme load transients and enables full rated performance without derating.

Power density

Operation at low temperature enables approximately double the power density through higher allowable current density, reduced conductor resistance, and higher-frequency operation with lower magnetic core losses. This can reduce the footprint per megawatt by up to 50%.

Optimised integration

An optimised temperature gradient is integrated across the AI factory, allowing power conversion, computation, and interconnect functions to operate at their most efficient temperature zones. This system-level thermal coordination maximises overall efficiency while preserving full functional capability across diverse workloads.

Enhanced reliability

Lower component stress, reduced parameter drift, and fewer thermal cycles materially improve mission-critical uptime, supporting 99.999% service level agreement targets.

Designed for practical deployment and integration

Zap Power’s technology is designed to integrate with existing data centre infrastructure, enabling a realistic pathway to adoption without requiring wholesale architectural replacement.

By targeting inefficiencies at the power layer, Zap Power delivers system-wide benefits that compound as AI infrastructure scales.

Want to delve deeper?

Speak to our team about integrating cryogenic power and cooling